GHI Smart Furnaces, in collaboration with the Gestamp Group, Betico, and Tecnalia Technology Center, proudly presents the NAIA project. This initiative aims to develop new equipment and tools that not only ensure efficient management of furnace and compressor consumption but also automate the detection of energy inefficiencies at the plant level. By reading and processing energy consumption and global production data, we aim to drive significant advancements in industrial efficiency.

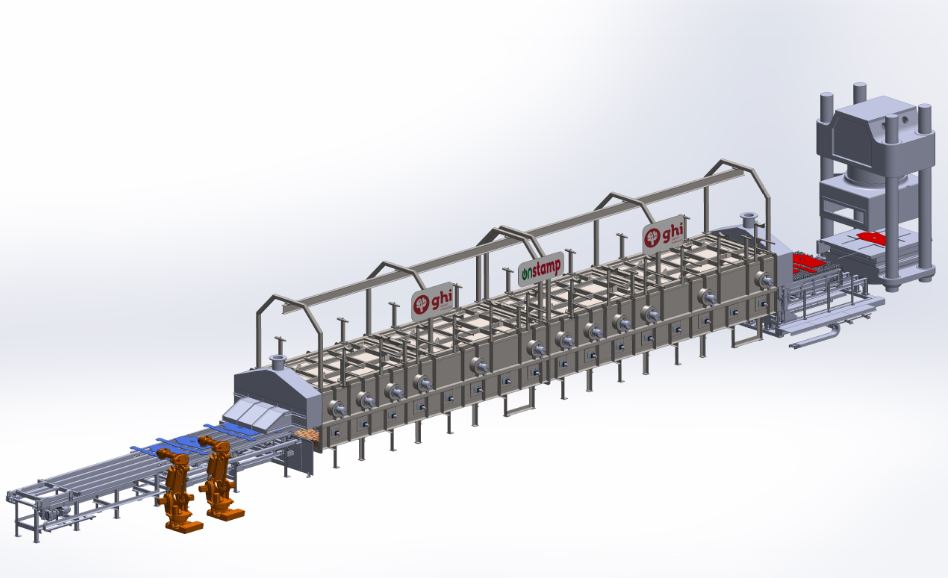

Introducing the ECO SMART Furnace NAIA

One of the standout results of the NAIA project is the development of the ECO SMART Furnace NAIA, a virtual oven model designed for Industry 4.0 control. This innovative furnace model leverages Data Analytics techniques to optimize control based on the target temperature of the piece, rather than the target furnace temperature, resulting in substantial energy savings.

Project Highlights:

- Collaboration and Innovation: Developed in partnership with the Gestamp Group, Betico, and Tecnalia, the NAIA project exemplifies collaborative innovation.

- ECO SMART Furnace NAIA: This virtual hot stamping furnace model aims for optimized control, focusing on energy efficiency and smart process improvement.

- Automation and Efficiency: Automates the detection of energy inefficiencies, providing a comprehensive solution for modern industrial challenges.

Financial Support

This project has been co-financed by the SPRI, Business Development Agency of the Basque Government, underscoring its importance and potential impact on the industry.

Embracing Industry 4.0 with Smart Process Improvement

The NAIA project is integrated into our broader Smart Process Improvement initiative. This includes advanced sensorization, digitalization, technical assistance, process consulting, and preventive maintenance. By adopting these technologies, plants can achieve greater control over production processes, significantly reducing energy consumption and operational costs while enhancing overall efficiency.

Advantages of the NAIA Project:

- Efficient management of energy consumption.

- Automation of energy inefficiency detection.

- Optimized control based on Data Analytics.

- Enhanced operational efficiency and sustainability.

- Collaboration with leading industry and technology partners.