Innovative Zinc Foundry and Steel Manufacturing Solutions

GHI is a leading provider of sustainable manufacturing solutions for the aluminium also iron, and zinc industries. Our Smart Plants are designed to maximize efficiency, reduce environmental impact, and meet the highest quality standards.

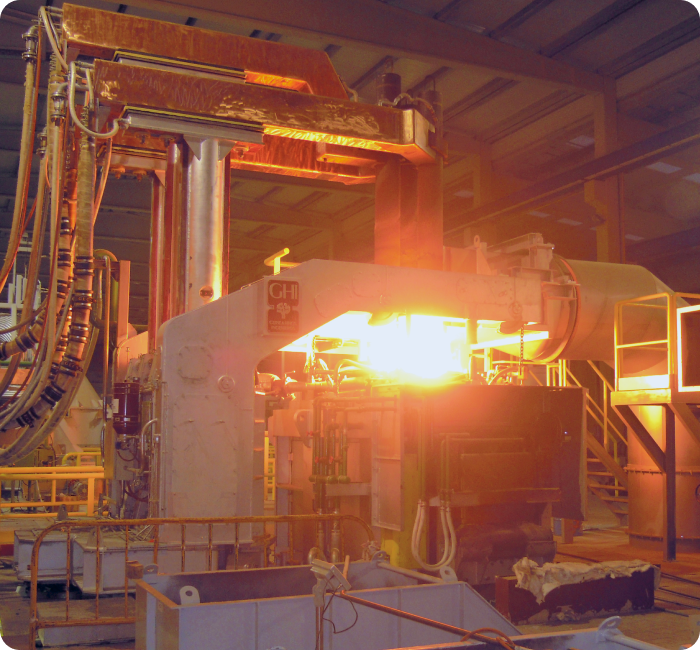

Commissioning and Upgrading Steelworks

GHI offers a comprehensive solution for modernizing and optimizing your steelworks, catering to the production of large quantities of molten iron and steel. Our integrated systems encompass Electric Arc Furnaces, Argon and Oxygen Decarburization, Ladle Furnaces, and Smart Heat Treatment Furnaces, all designed to minimize manual intervention and enhance operational efficiency.

-

Highly precise and controlled metal transfer

Our sophisticated system optimizes energy consumption, reducing refractory consumption and electrode and electricity usage, while also ensuring the protection of furnace components.

-

Simultaneous Engineering Approach

We adopt a concurrent engineering approach, leveraging over 80 years of experience, to tailor our solutions to your current and future needs, ensuring seamless integration and long-term performance.

-

Energy-Efficient Furnaces

Our energy-efficient smart furnaces for steel mills maximize productivity and minimize human intervention, leading to significant cost savings and environmental benefits.

Highly Automated Iron Foundries

GHI assists in iron foundries with our furnaces designed to produce highly automated cast iron and liquid steel for small to medium-sized applications, catering to the automotive industry and beyond. Our modular facilities can be customized to meet your specific needs, while our fully automated heat treatment processes minimize manual labor and maximize productivity.

-

Flexible Modular Design

Our plants are designed to be modular, allowing for customization to meet your unique requirements and scalability to accommodate future growth.

-

Highly Automated Processes

Our furnaces and heat treatment processes are designed for maximum automation, minimizing labor requirements and maximizing production efficiency.

-

Engineering Excellence

With over 80 years of experience, GHI brings a wealth of engineering expertise to optimize your iron foundry operations.

High-Quality Zinc Cathode Melting Plants

The production of zinc coils begins with the melting of 99.9% pure metallic cathodes obtained during the electrolysis process using our state-of-the-art Cathode Melting Furnace and Alloying Furnace. Our automated loading system introduces the cathodes into the induction furnace, where controlled alloying additives are carefully introduced to create the liquid alloy. The molten zinc is then transferred to casting machines, producing various commercial formats and zinc alloys demanded by the market.

-

Collaborative Design

Our plants are designed collaboratively with all stakeholders in the process, ensuring that the solution meets the specific needs of each customer.

-

Precision Process Control

Our integrated management and control system allows for real-time monitoring and optimization of process parameters, ensuring consistent product quality.

-

Consistent Temperature Control

Our induction furnaces for melting and alloying provide precise temperature regulation, ensuring the production of high-quality zinc coils.

High-Speed Zinc Coil Manufacturing Plants

We support your zinc coil production using the Cathode Melting Furnace and Alloying Furnace, ensuring high-quality and consistent results. The molten metal is transferred to a continuous casting machine where it solidifies to the desired thickness. Subsequently, the solidified zinc undergoes heating in our high-speed convection furnaces and continuous rolling to achieve the final desired thickness. We provide comprehensive furnace design and supply auxiliary equipment for both the foundry and heating processes in the rolling area.

-

Precise Temperature Regulation

Our advanced management and control system ensures precise temperature regulation throughout the entire production process.

-

High-Speed Heating Equipment

Our Smart Furnaces are equipped with cutting-edge technology that enables rapid and precise heating of zinc coils, ensuring uniform temperature distribution.

-

Simultaneous Engineering Approach

Designed collaboratively for all stakeholders in the process, aiming to find a solution that best meets current and future customer needs.

-

Energy Efficiency

A high degree of process automation allows for significant cost savings and environmental benefits, aligning with GHI's commitment to sustainable practices.

Let Diego Angulo help you today

Diego Angulo, Engineering Manager, is here to answer your questions about our Smart Plants solutions for Zinc and Steel. Reach out for a quick, personalized consultation to explore the capabilities of our cutting-edge facilities.