In response to the growing demand for a circular economy, environmental regulations, and a highly competitive market focusing on product quality, process productivity, and profitability, the aluminum sector is driving top equipment suppliers to innovate. GHI Smart Furnaces leads the way by developing cutting-edge technologies and processes to maximize aluminium dross recovery.

When aluminum is melted, the generated dross must be removed to ensure high-quality aluminum. Black dross from secondary melting operations can contain 5% to 30% aluminum, while white dross from primary smelters is richer, with 20% to 80% aluminum content. The aluminum in both types of dross can be recovered through subsequent melting processes.

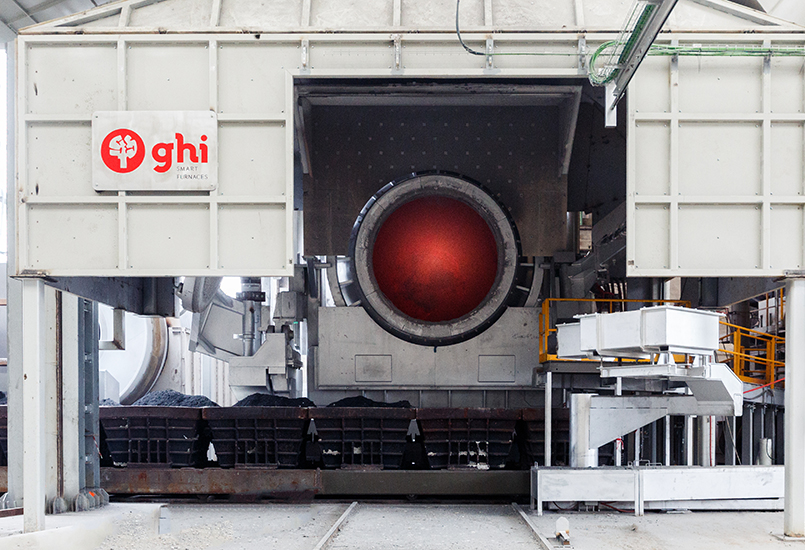

The Smart Tilting Rotary Furnace is the most effective technology for processing dross, maximizing energy efficiency and metal recovery.

GHI’s Experience in Dross Recovery Plants

GHI Smart Furnaces, a leading European furnace supplier, has extensive experience in aluminum recovery technologies. They have developed advanced equipment to enhance the profitability of dross recovery plants.

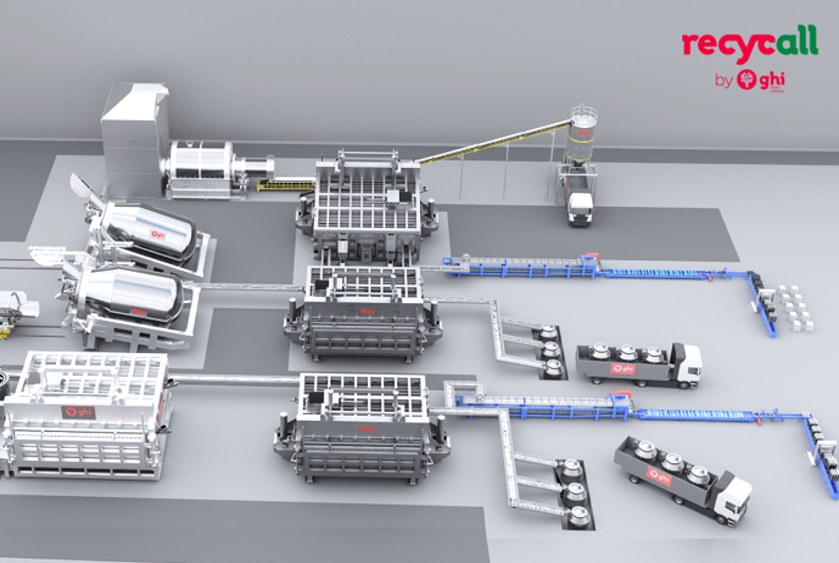

One notable project is the dross recovery plant in Germany, designed and supplied by GHI in collaboration with Befesa, with a total input capacity of 140,000 tpy. Additionally, GHI has supplied two aluminum recycling plants in Spain, each with a capacity of 100,000 tpy.

These state-of-the-art plants utilize the most efficient, safest, and sustainable technologies. The Bernburg plant in Germany is a leader in the dross recovery industry, producing ingots and liquid aluminum primarily for the automotive and packaging industries.

ROTADROSS

Recovering Aluminium from Dross

The primary equipment for aluminium dross recovery is the Smart Tilting Rotary Furnace.

GHI Smart Furnaces developed the ROTADROSS, a new concept in tilting rotary furnaces. This innovation provides profitable metal yields and produces significantly less contaminant waste compared to traditional models. Numerous references in Europe and Latin America validate these benefits.

The value proposition of the ROTADROSS includes:

- Oxy-fuel burners that produce a high-intensity flame and better heat transmission to the load.

- Availability in different sizes from 10 to 65 t capacity.

- Reduction of salt usage by 50% compared to other rotary industrial furnaces.

- Lower costs for fume collection and filtration equipment due to fewer combustion gases.

- Easy emptying and cleaning thanks to the tilting body of the furnace.

- Proven lining designs and qualities that increase equipment lifecycle and minimize maintenance costs.

- 4.0 technology developed by GHI for process characterization, increasing control and optimizing cycle time.

SALT SLAG COOLING SYSTEM

Increasing Profitability and Minimizing Environmental Footprint

The salt-slag from the rotary tilting furnace usually contains 3% to 10% residual metallic aluminum. The salt slag cooling system, designed by Befesa and supplied by GHI through their technological partnership, captures fumes and prevents aluminum oxidation, increasing recovery and drastically reducing cooling space requirements.

This system significantly reduces fumes, emissions, and odors. The principle of operation of GHI’s salt slag cooling system involves cooling the slag below 400ºC within minutes, followed by classification based on size and metal content. The cooling system uses a fit-for-purpose conveyor to transport the slag, avoiding traditional baskets.

HOLDING FURNACES

Ensuring Aluminium Quality

Dross recovery plants also utilize reverberatory holding furnaces designed for receiving, holding, alloying, and preparing molten aluminum. The open front design allows access to the entire chamber for cleaning and skimming, optimizing product quality.

These furnaces feature a bath agitation system using porous plugs to homogenize temperature and chemical composition, resulting in premium quality metal. They also include automatic tilting systems for efficient casting control, with a proportional valve, tilt meter, and laser level monitoring system.

BEYOND 4.0 PLATFORM

Smart Plant Integration

GHI offers a complete and intelligent plant concept for dross recovery, providing the highest market performance and a 4.0 solution that transforms data-driven insights into data-driven actions. All equipment is sensorized, with captured data analyzed on the Beyond 4.0 platform using custom algorithms and big data systems under robust cybersecurity protocols.

GHI engineers analyze the dross recovery process to optimize cycle times, improve process control, and offer predictive and preventive maintenance worldwide.