NAIA: New Equipment and Eco-efficient Tools for Industry 4.0 — This project, developed in collaboration with the Gestamp Group, Betico, and Tecnalia technology center, aims to develop new equipment and tools that allow not only efficient management of the consumptions of furnaces and compressors but also provide a solution that enables the automation of detecting energy inefficiencies at the plant level based on the analysis of energy consumption and overall production data.

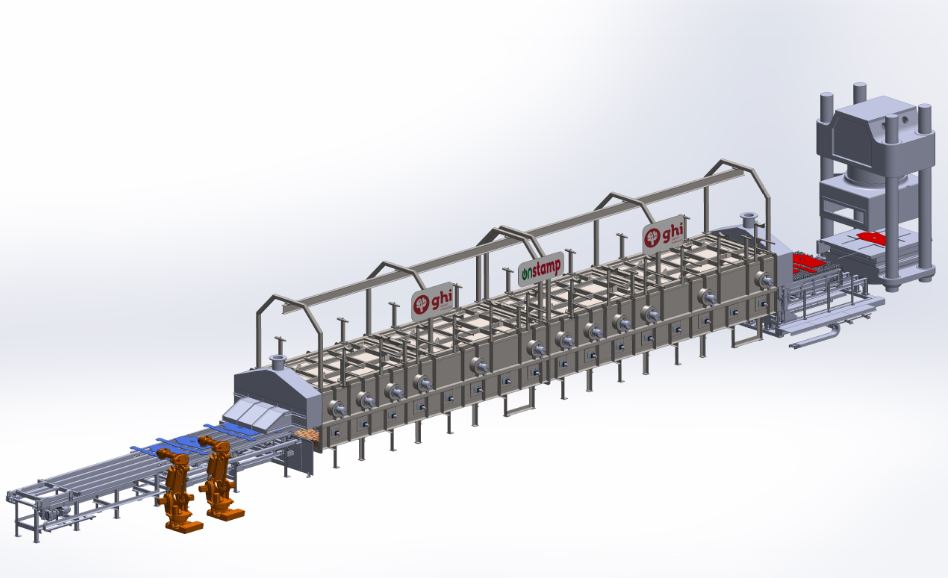

The new furnace model resulting from the project is described below:

- ECO SMART Furnace NAIA: A virtual oven model advancing towards an Industry 4.0 control paradigm.

The project will develop a virtual hot stamping furnace model and an optimized control of it. The proposed control, based on Data Analytics techniques, will operate based on the target temperature of the piece rather than the target furnace temperature, resulting in significant energy savings.

This project, NAIA, has been co-financed by the SPRI, Business Development Agency of the Basque Government.