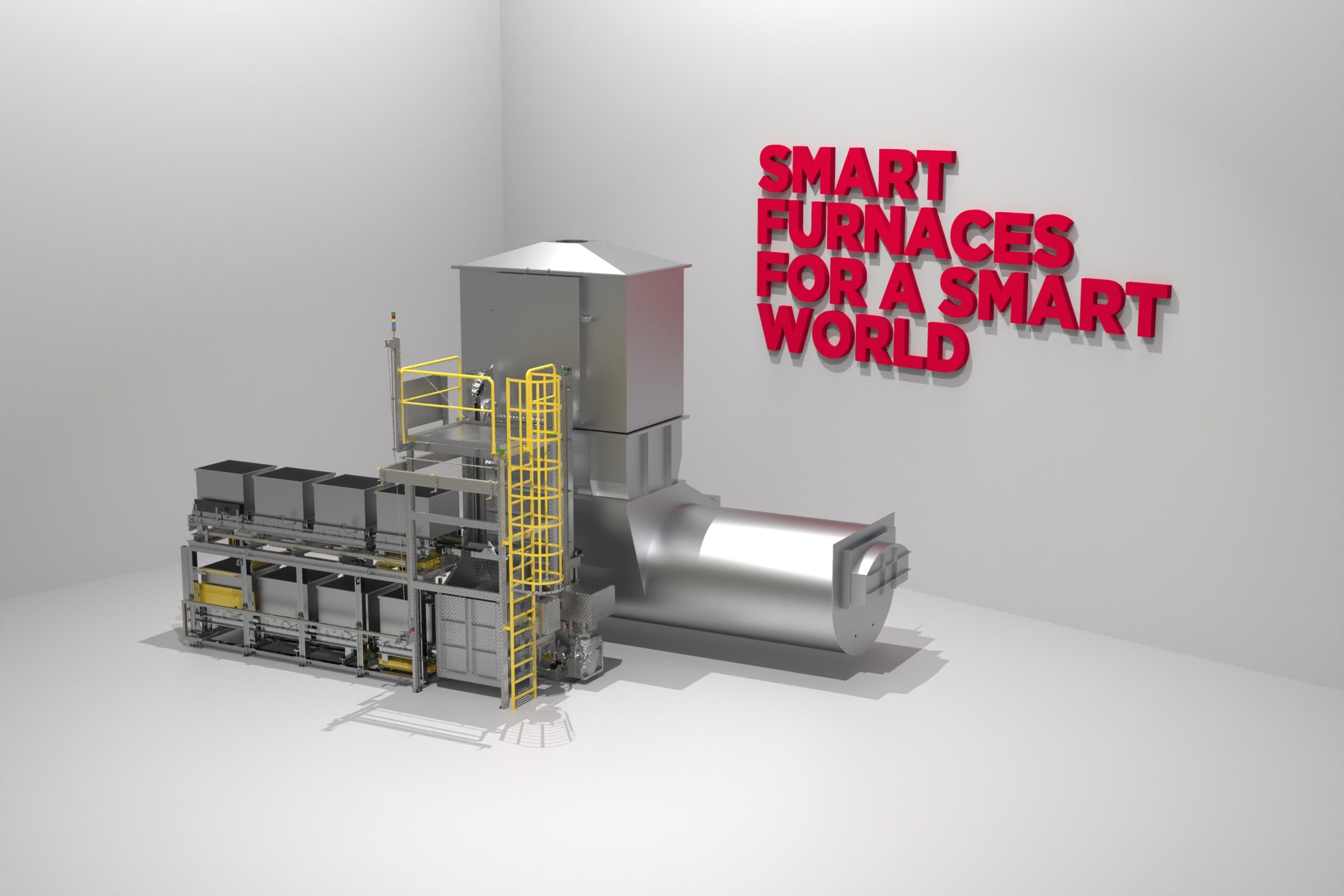

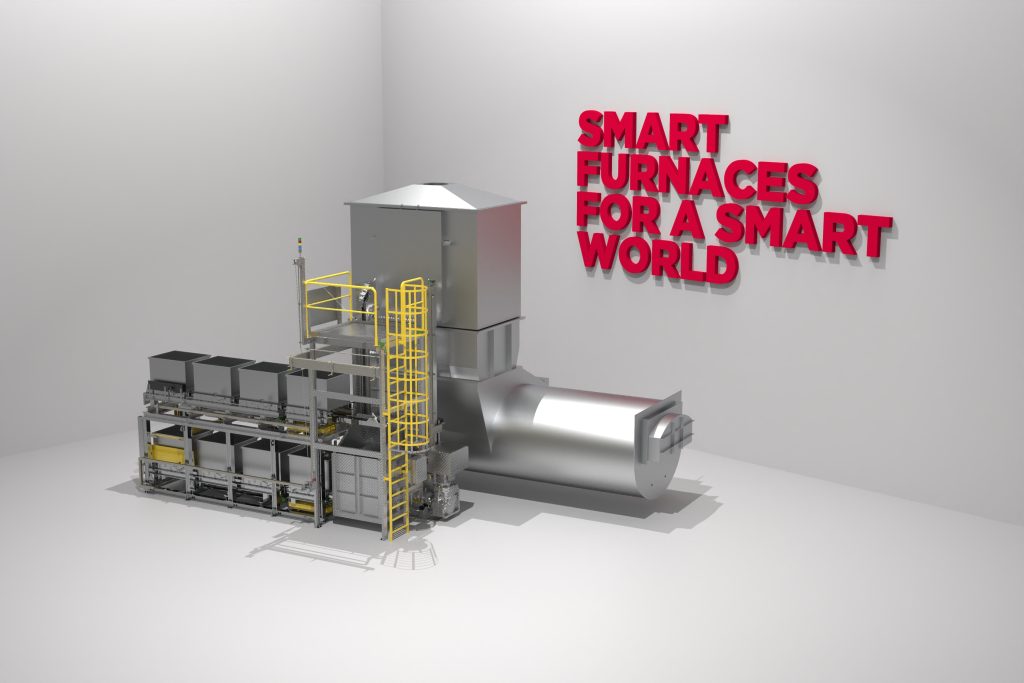

Prime Casting Plant: Melting tower with integrated holding furnace and automatic loading system for automotive company

One of the global suppliers of die casting components for the automotive industry trusted once again in GHI Smart Furnaces. The customer’s objective was to achieve the highest metal yield from aluminium and a fully automated casting process in a reduced layout. GHI supplied the Prime Aluminium Casting Plant, consisting of a melting tower with integrated holding chamber for melting aluminium ingots and inhouse returns, and the fully automated loading system. The plant is fully integrated into the 4.0 industry.

Integral solution

After a thorough review of the melting and casting process, we supplied the Prime casting plant. The client opted for our technology after checking the high performance of our aluminium furnaces and the possibility of having an automated, controlled, and efficient aluminium casting process that provided the best quality aluminium in a restricted layout.

The aluminium casting facility is fully sensorized and integrated into the Beyond 4.0 platform. It consists of a melting tower furnace with holding capacity and an integrated automatic loading system with two level storage buffer.

The furnace, is a melting tower with a production of 3 t/h with an integrated holding chamber with a capacity of 4 t. This tilting furnace is recommended for melting ingots and aluminum returns.

With our furnace design, the client will obtain minimum oxidation losses and a guaranteed metal recovery greater than 99.5%. The high energy efficiency of our furnaces is comparable to that obtained in furnaces equipped with regenerative burners.

The optimium quality of the liquid aluminium provided by GHI’s furnace, requires complete accessibility to facilitate cleaning operations. The skimming door covers the entire width of the melting chamber. This design, together with the use of our automatic skimming machine, specially designed to facilitate the complete cleaning of the melting chamber, ensures the quality of the obtained metal and prevents the subsequent appearance of hard points on the final components.

The two-level loading system for aluminium ingots and baskets with inhouse returns, includes a feeding system with a buffer and a lifting and tilting loader that triggers automatically. This automatic loading system gives autonomy to the aluminium casting process and enables high levels of production and safety.

Finally, the molten aluminium will be transferred to transport ladles to feed the dosing furnaces and continue the casting process.

At GHI we are continuously optimizing the design and engineering of the two-chamber melting and holding furnace to ensure the equipment reliability, reduce metal losses and fuel consumption and improve the handling of the installation thus increasing the plant’s safety.

Our equipment knowledge, its operations and proper maintenance through 4.0 technologies, allow us to maintain the performance of the industrial furnace and equipment throughout their life cycle.

Advantages

- Maximum metal yield > 99,5%

- Minimum fuel consumption < 65Nm3/t

- Minimum personnel requirement due to the high degree of automation of the loading process and the storage buffer

- Maximum availability of the furnaces

- Total control and monitoring of consumption and load with advanced sensorization and 4.0 technologies

- High temperature uniformity and aluminium quality

- Total compliance of safety and environmental regulations

- Integration to 4.0 industry