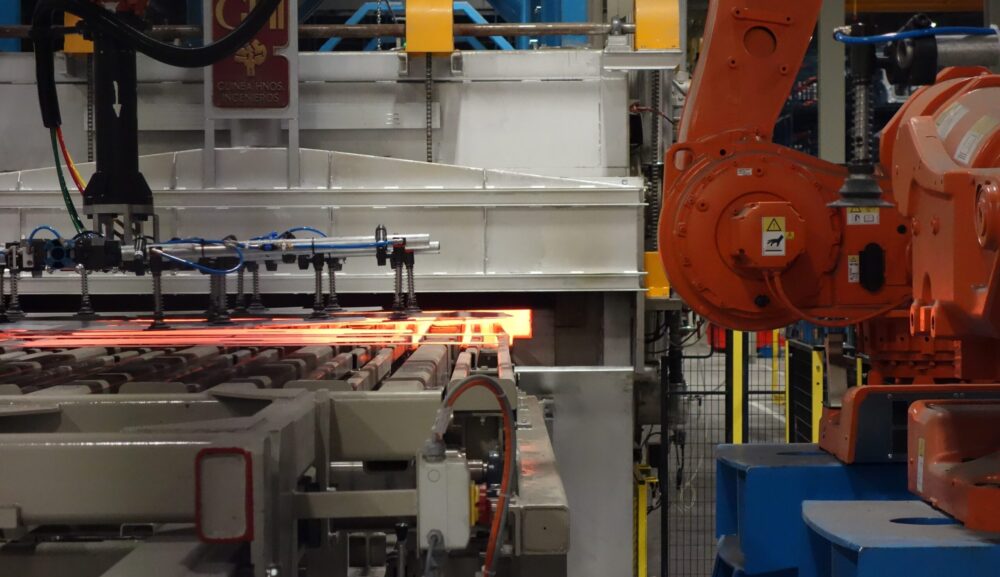

GHI Smart Furnaces is revolutionizing the stamping industry with its groundbreaking COLD-HOT 4.0 technology. This advanced solution, developed in collaboration with the Gestamp Group and the technology centers Tecnalia, IK4, and Autotech Engineering, addresses the market’s evolving needs for efficient and versatile stamping processes.

Cutting-Edge Stamping Solutions

The COLD-HOT 4.0 project encompasses several innovative lines of work:

- Multistep Technology: This approach involves developing a new material and hot stamping production process that reduces cycle time to just 2-3 seconds, significantly boosting productivity.

- IPHS Method: The Indirect Process for Hot Stamping (IPHS) combines hot and cold deformation, offering improved results and efficiency.

- Softzone 2.0: This technology allows precise temperature control in specific areas of the stamped pieces, endowing them with varied mechanical properties to meet diverse application needs.

- Manufacturing 4.0: GHI has also developed a remote control and monitoring method, enhancing the production process’s oversight and adaptability.

- Cold Line Innovation: Advances in hydraulic presses increase cadence, optimizing the cold stamping process.

Advancements in Stamping Furnace Technology

A key innovation emerging from this project is a new concept of hot stamping furnace, which addresses the limitations of traditional roller hearth furnaces. This novel furnace design is currently in the patent process, showcasing GHI’s commitment to leading-edge technology and continuous improvement.

Collaborative Efforts and Funding

The COLD-HOT 4.0 project has been co-financed by the SPRI, Business Development Agency of the Basque Government. This collaboration underscores the project’s importance and potential impact on the stamping industry.

Transforming the Stamping Industry

By integrating these advanced technologies, GHI Smart Furnaces is setting new standards in the stamping industry. The COLD-HOT 4.0 project not only enhances efficiency and productivity but also ensures superior quality and versatility in stamped products.

For more information on GHI Smart Furnaces and their innovative solutions, visit GHI Smart Furnaces.