At GHI Smart Furnaces, we are thrilled to announce the completion of a state-of-the-art aluminium billet manufacturing plant in Mexico. This project highlights our commitment to innovation, efficiency, and sustainability in the aluminium industry.

The project developed in two phases to meet increasing market demands. The first phase, inaugurated in May 2019, equipped the plant with advanced melting, casting, and billet homogenizing technology. This offered a production capacity of 20,000 tons per year. In the second phase, we doubled the plant’s capacity to 40,000 tons per year by adding new equipment.

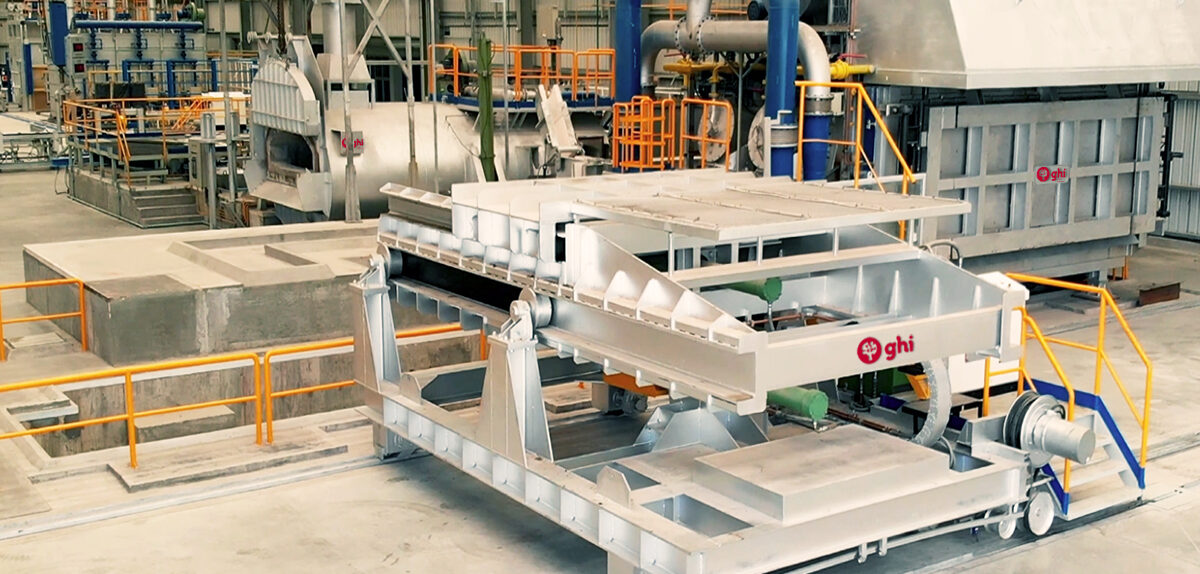

Integral Solution for Aluminium Billet Manufacturing

Our approach showcases the comprehensive solutions GHI Smart Furnaces provides. The first phase included engineering, supplying, installing, and commissioning equipment for aluminium melting and homogenizing, as well as the casting machine. Key installations included a 25-ton capacity reverberatory melting furnace with regenerative burners. This 6t/h melting furnace features an open front for fast and efficient loading and skimming. Its regenerative burners reduce energy consumption and environmental impact—key goals for our client.

Additionally, we installed a 25-ton reverberatory holding furnace equipped with porous plugs to maintain the liquid aluminium and ensure temperature uniformity and optimal alloy homogeneity.

We cast the billets on a vertical casting machine, ensuring the highest quality of the final product. For heat treatment, GHI supplied 25-ton capacity heat treatment furnaces, which are designed to heat only the load, achieving significant energy savings.

Finally, we cool the billets in a controlled cooling chamber with a series of roof-mounted fans for efficient air circulation.

Expanding Capacity in the Second Phase

The second phase of the project aimed to double the production capacity to 40,000 tons per year. This involved installing another 25-ton reverberatory melting furnace and a 40-ton billet homogenizing furnace with an integrated loading machine and cooling chamber.

This new equipment has significantly enhanced the plant’s melting rate and heat treatment capacity, meeting our client’s ambitious objectives.

Key Advantages of the Aluminium Billet Plant

- Energy Efficiency: Use of state-of-the-art regenerative burners and optimized furnace design.

- Process Efficiency: Fast and efficient charging in the melting furnace and high-quality, consistent billets.

- Environmental Impact: Reduction in energy consumption and emissions.

- Automation: Advanced process automation for improved reliability and performance.

- Quality: Optimum homogeneity in the aluminium alloy due to the use of porous plugs in the reverberatory furnace.

- Economic Savings: Significant cost reductions from energy savings and efficient operations.

We are proud to contribute to the growth and sustainability of the aluminium industry with this advanced aluminium billet plant. Learn more about our innovative solutions at GHI Smart Furnaces.