How do you turn painted, oily, and mixed aluminium scrap into clean metal without losing yield, or money?

Traditional furnaces struggle here, often trading recovery for complexity. Salt-flux rotary systems can help, but they leave behind salt slag that carries both cost and risk.

After more than 25 years at GHI, I have learned that scrap is almost never clean. The real question is: what technology can handle these messy realities while still making economic sense?

That is where plasma deserves a closer look.

A Short History of Plasma in Industry

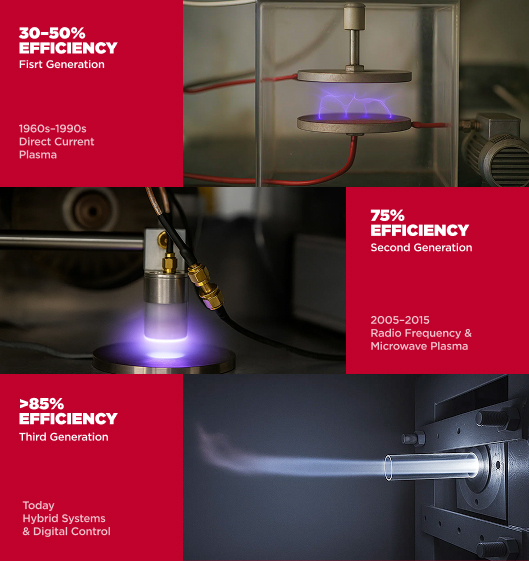

Plasma is not new. In the 1960s it was used for welding and cutting.

By the 1990s, companies such as Alcan in Canada were already applying plasma to treat aluminium dross, processing thousands of tons every year. But those early systems were far from perfect: efficiencies rarely exceeded 50%, electrodes wore out quickly, and costs were high.

The second generation (2005–2015) brought radiofrequency and microwave torches, pushing efficiencies higher, closer to 75%.

Today, third-generation hybrid systems with digital control achieve more than 85% efficiency.

What Plasma Really Is

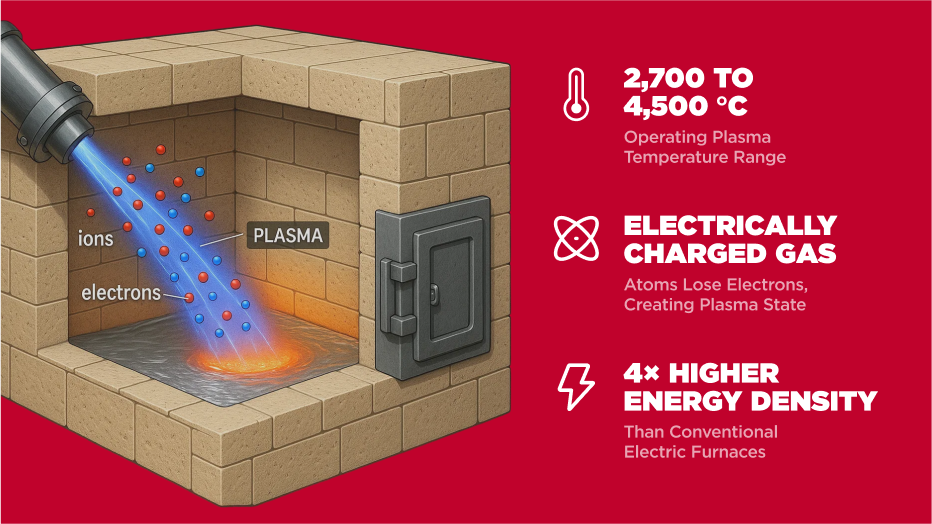

Plasma is sometimes mistaken for fire. It is not. It is the fourth state of matter: a gas that becomes electrically charged when atoms lose electrons.

Aluminium melts at about 660 ºC. Plasma furnaces can reach up to 4.500 ºC — far beyond what is needed to melt metal.

In practice, scrap coated with paint, oil, or plastic is a problem for conventional furnaces. Plasma’s extreme heat breaks down organics and still recovers clean aluminium.

It is like having a tool that not only melts the metal but also “cleans” it in the same process.

Why Plasma Matters for Aluminium Recycling

Anyone who has visited a scrap yard knows the truth: aluminium does not arrive clean and shiny. It comes mixed with oils, coatings, plastics, and moisture. Traditional furnaces need long pretreatments to clean this scrap. That costs time, money, and often leads to significant metal losses as dross.

• Rotary salt-flux furnaces handle contaminated scrap, but they rely on large amounts of flux. This creates salt slag, a residue that must be treated and disposed of at significant cost.

• Reverberatory furnaces avoid salt, but they require cleaner scrap and lose more aluminium to dross.

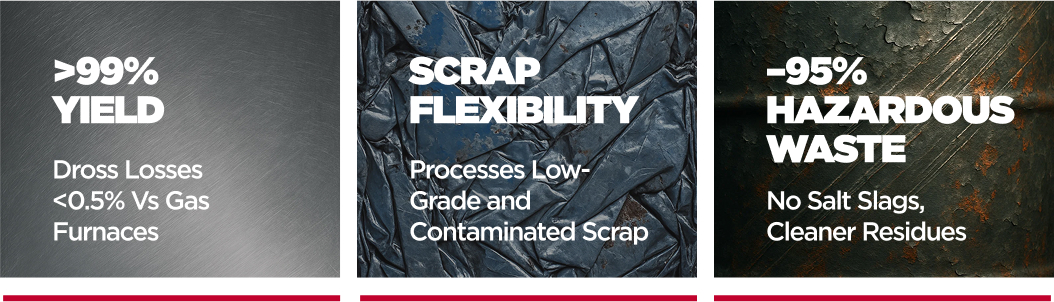

Plasma changes the equation. It delivers three clear benefits:

• It recovers more of the metal.

• It accepts contaminated or low-value scrap.

• It avoids producing hazardous residues such as salt slags.

Evidence from Research and Industry Cases

Skeptics often ask: is plasma really proven, or just another laboratory idea? It is a fair question.

Research. A 2024 review by Kusano & Kusano (Materials) confirmed what industry is seeing today: modern plasma furnaces reach efficiencies well above conventional furnaces, often exceeding 80% in practice. More importantly, they melt faster and demand less scrap pre-cleaning compared to induction or gas systems.

Pilots. Demonstration projects confirm consistent points: shorter melting times, stable operation with contaminated scrap, and major reductions in carbon dioxide emissions compared to gas furnaces. When powered by renewables, emissions can approach zero. The challenge is still electricity cost, though this is easing as renewable power becomes cheaper.

Industry.

• Alcan (Canada): plasma dross treatment operating since 1992, processing tens of thousands of tons annually.

• Scepter Inc.: rotary plasma furnace achieving high yield without generating salt slags.

• Retech Systems: plasma arc melting (PAM) for specialty and high-value metals.

• PyroGenesis + Constellium: demonstrator furnace under development, expected to start in 2026.

Taken together, these results show that plasma is no longer confined to the lab. It is already applied in industrial settings, particularly where scrap complexity is high and recovery value justifies the process.

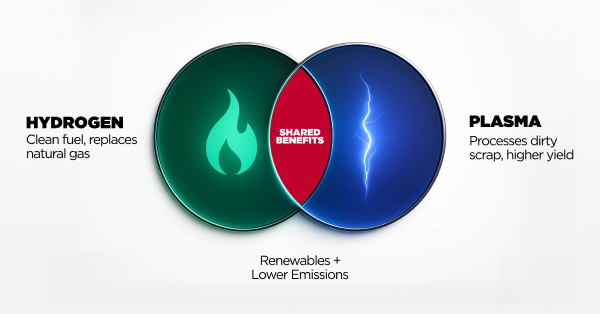

Plasma vs. Hydrogen – Two Different Paths

Some ask me: if hydrogen is the “fuel of the future,” why do we still need plasma?

• Hydrogen is a clean fuel. It burns to produce only water vapor and can replace natural gas in furnaces. But the process logic stays the same: scrap still needs to be clean, and pre-treatment steps remain.

• Plasma is different. It is not just another fuel; it is a process transformation. Plasma accepts dirty or mixed scrap, delivers higher yields, and drastically reduces residues.

Think of it this way:

• Hydrogen cleans the fuel side of the process.

• Plasma cleans the scrap side of the process.

When operations deal with conventional, cleaner scrap, hydrogen has clear value. But when the challenge is contaminated or low-grade scrap, plasma offers the decisive advantage.

| Parameter | Plasma Furnace |

Hydrogen Furnace |

Induction Furnace |

Natural Gas Furnace |

|---|---|---|---|---|

| Operating temp. |

2700–4500 ºC | Similar to gas |

Not a pplicable |

1000–1200 ºC |

| Metal yield |

>99% | Similar to gas |

90–95% | 88–97% |

| Pretreatment required |

Minimal | High | Very high | High |

| Direct emissions |

Zero* | H₂O vapor (no CO₂) |

Zero* | CO₂, NOx, particulates |

| Scrap flexibility |

High | Low | Very low | Low |

| CAPEX payback |

0.6–2.6 yrs | Variable | 2–4 yrs | Variable |

Notes: Zero, with renewables, indicates no direct emissions when powered by renewable electricity. Values reflect typical ranges reported in industry and literature.

My Vision as Engineer

I have learned that the “right” technology is not the newest or the cheapest, but the one that solves the right problem in the right context.

For plasma, challenges remain — from initial investment to electrode lifetime and integration with other solutions. Yet the gains are undeniable when dealing with complex scrap: higher yield, fewer residues, and a realistic path to deep decarbonization.

Our role at GHI is to continue monitoring and learning from these technologies, so that when the right conditions align, we are ready to support customers in making informed decisions.

Aluminium’s Next Frontier

The real question is not whether plasma works, but how it fits into your operation.

What does your scrap mix demand? What is the true cost of energy in your plant? And to what extent can cutting emissions become your competitive advantage?

Disclaimer

This article is educational and summarizes published research and pilot experiences regarding thermal plasma in aluminium furnaces. GHI Smart Furnaces does not commercialize plasma solutions at this time. Results cited refer to specific studies and operating contexts; outcomes may differ at industrial scale.

References

- Kusano, R. & Kusano, Y. (2024). Applications of Plasma Technologies in Recycling Processes. Materials. Link

- Kusano, R. et al. (2023). Hybrid Plasmas for Materials Processing. Materials, 16. Link

- Hydro Sunndal (2024). Plasma Retrofit Pilot Project. Industry case report. Link

- Novelis Latchford (2025). Hydrogen Trials in Aluminium Recycling. Industry case update. Link

- Springer (2023). Advances in Plasma Arc Melting. Link

- Programmaster.org (2023). Conference Proceedings: Plasma & Recycling. Link

- Metals & Mining Review (2024). Decarbonization Pathways for Aluminium. Link